Balmoral takes seamless bend stiffener connector to market

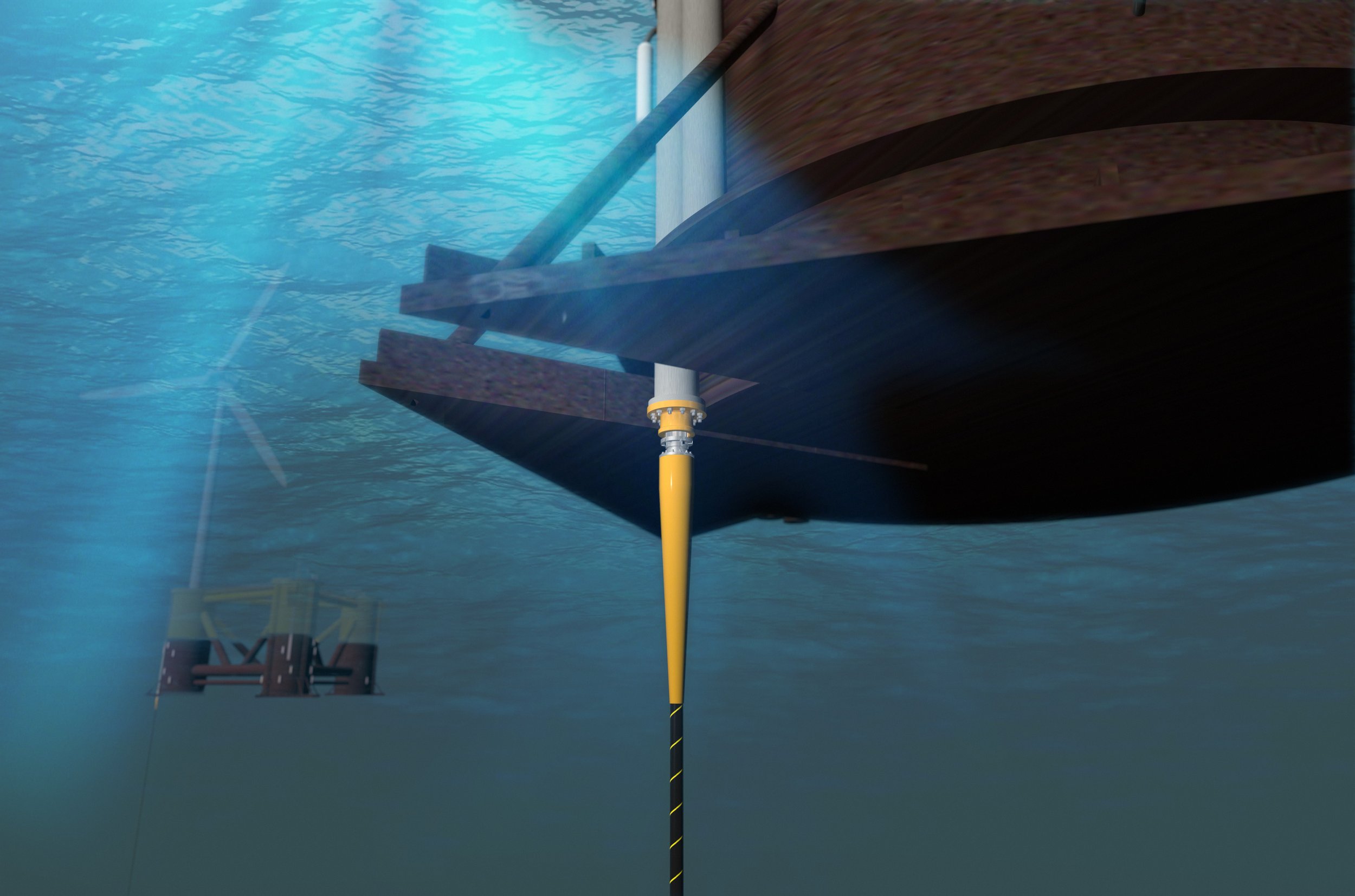

Balmoral bend stiffener connector (BSC) illustrated in-situ

Balmoral, the Aberdeen-based energy industry specialist, has introduced a number of subsea solutions through its innovation-focused road map programme over the past few years.

These include Balmoral HexDefence and Balmoral FibreFlex, scour and cable protection systems respectively for the offshore wind sector. The latest product solution to be brought to market is a bend stiffener connector.

Bend restricting devices, which include stiffeners and restrictors, are vital pieces of equipment that are used across the offshore wind and traditional oil and gas sectors where there is a requirement to control the bend radius of a pipe, cable or umbilical.

They are usually attached at topside or seabed connection areas and are typically conically shaped polyurethane mouldings with a cylindrical bore that fits over the asset.

In seamlessly integrating dynamic bend stiffeners with offshore structures, the Balmoral BSC features diverless installation and an elevated level of operational performance.

Balmoral engineering and projects director, Fraser Milne, said: “With the BSC, operational readiness is achieved swiftly and we believe establishes an unparalleled benchmark for reliability and efficiency.

“By enabling a seamless fusion of dynamic bend stiffeners with offshore structures our commitment to pioneering engineering solutions for the offshore energy sector is again demonstrated.”

Diverless installation lies at the heart of this innovation while the design and manufacturing process adheres to API 17L standards. This commitment to operational efficiency is further highlighted by the incorporation of a reusable pull head which not only enhances installation timelines but also adds practicality to the overall process, the company claims.

The full system consists of a lead-in cone, BSC and dynamic bend stiffener. The BSC is drawn through a bellmouth located beneath a floating platform. As the BSC latching system engages with the bellmouth the anchoring mechanism comes into action. This latch secures the mechanism during descent and maintains system stability as the anchors find their place on the tapered neck of the bellmouth.

“This is another example of how Balmoral continues to push technological boundaries to the benefit of the offshore energy sector”, says Milne.

“The BSC and many other industry-leading solutions will be available for discussion on our stand at Offshore Europe in Aberdeen, 5-8 September”.

About Balmoral Comtec

Balmoral Comtec is a division of Balmoral Group which was established in 1980 by chairman and managing director, Sir James Milne CBE. The company has built an enviable reputation in the design, development and delivery of buoyancy, protection and insulation products for the global offshore energy sector.

As an independent company, headquartered in Aberdeen, Balmoral has around 300 people based at its facility in the city and a global presence spanning Europe, North America, South America and Asia Pacific. Group-wide, the company employs approximately 600 people.

An unrivalled production capacity within its 250,000sq ft custom-built facility enables the company to provide multi-product, agile and flexible manufacturing with after-sales support delivered by the Balmoral Technical Helpdesk.