Hardide Coatings launches first product in new ready coated component range

Loading a Hardide® coating reactor

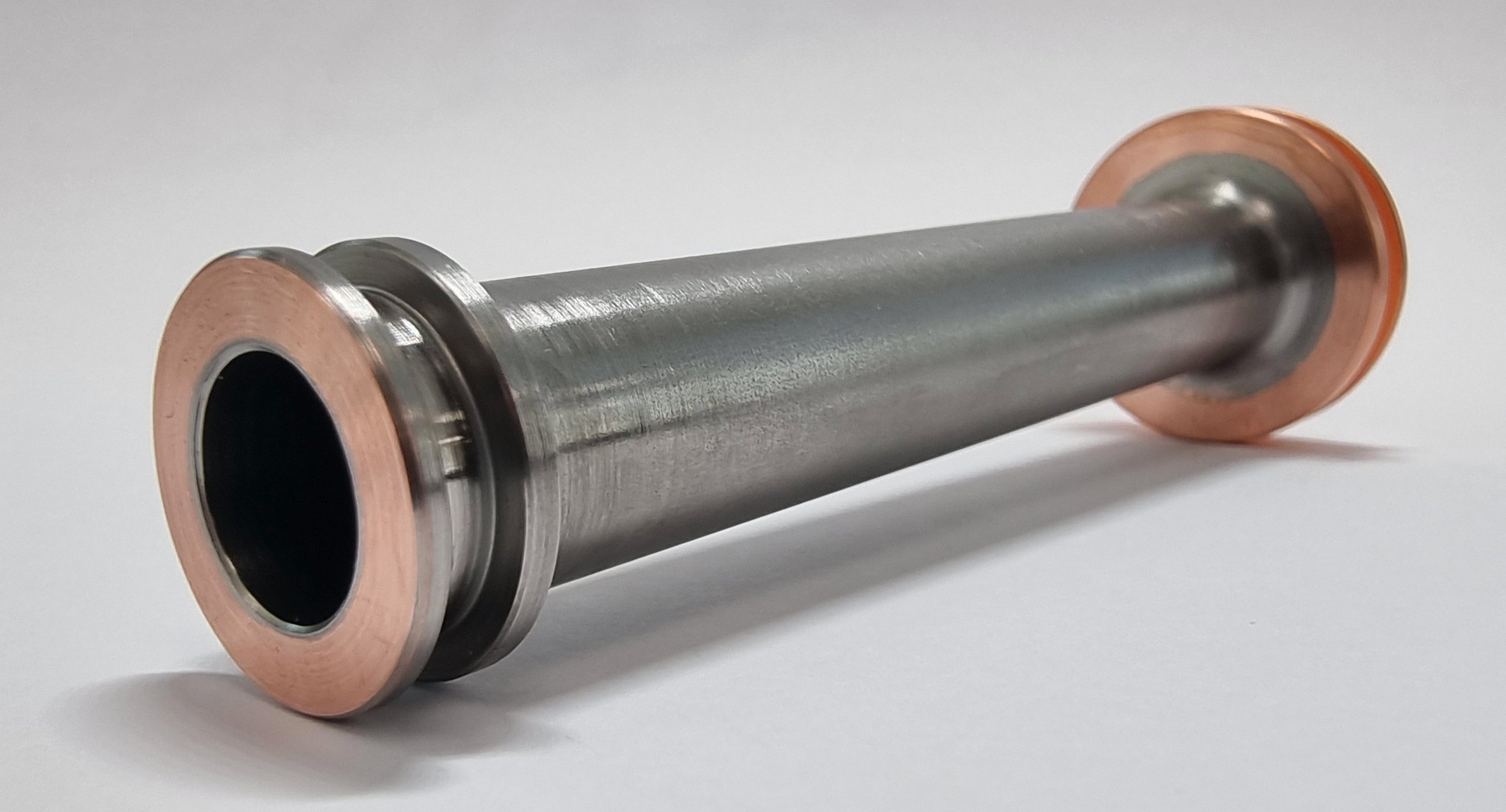

Hardide® coated HVOF copper nozzle extends life by up to 40x

Hardide Coatings, the provider of advanced surface coating technology, has launched the first in a new range of ready coated and enhanced components with a JP-5000 4” copper nozzle used in High-Velocity Oxy Fuel (HVOF) thermal spray coating.

The tungsten/tungsten carbide-based Hardide® chemical vapour deposition (CVD) coating is proven to extend the operational life of HVOF thermal spray copper nozzles by 5 to 40 times when spraying carbide or metallic-based powders. The ready coated nozzles include O-rings suitable to withstand the higher temperatures generated in longer periods of service.

Hardide® Ready Coated JP-5000 4” Copper Nozzle for HVOF Spray Gun

Steve Paul, Interim CEO of Hardide Coatings commented: “This is an extremely exciting new product development which offers significant performance, cost and environmental advantages to users of HVOF equipment. By Hardide® coating the internal diameter of copper nozzles used in thermal spraying, our enhanced component offers superior wear resistance and reduced pickup. This significantly extends the working life of the part thus improving productivity and reducing the spraying cost. We have had a lot of interest from OEMs and thermal spray companies in transforming the performance and durability of their HVOF spray equipment and we were pleased to ship our first production orders this week.

“The coated JP-5000 4” nozzle is the first in a range of Hardide® ready coated copper nozzles of varying sizes and other OEM equipment which we intend to launch on an ongoing basis.”

The extremely hard and homogeneous properties of the Hardide coating minimise pickup inside the nozzle when spraying metallic materials. This prevents material dislodging and forming a defect in the HVOF coating, therefore improving coating quality, reducing downtime and the cost of spraying. The life of the ready coated nozzles spraying metallic materials is extended up to 40 times compared to uncoated nozzles. When spraying carbide powders, the Hardide coating extends the life of the nozzles by 5 times.

Cross section of an uncoated copper nozzle with metallic pickup showing after 1.5hrs service

Cross section of a Hardide® coated copper nozzle after 22hrs+ service with Stellite 6 Powder showing no pickup present

Moreover, the nozzle has to be exchanged less often which decreases the risk of breaking the water circuit, while lack of nozzle clogging reduces the likelihood of spits or unmelted agglomerations of powder becoming embedded in the spray coating thereby eliminating the need for rework.

The Hardide coating is compatible with a wide range of coating materials used in HVOF processes, allowing for seamless integration with existing coating systems.

The company has been trialling the product with a global OEM in the US and coating services companies in Germany and Italy. The copper nozzles will be manufactured in Germany and coated at Hardide Coatings’ UK manufacturing facility for shipping globally.

The Hardide coated JP-5000 4” copper nozzles are being sold in fully recyclable packaging.

About Hardide Coatings

Hardide Coatings develops, manufactures and applies advanced technology tungsten carbide/tungsten metal matrix coatings to a wide range of engineering components.

Its patented technology is unique in combining in one material, a mix of toughness and resistance to abrasion, erosion and corrosion; together with the ability to coat accurately interior surfaces and complex geometries. The material is proven to offer dramatic improvements in component life, particularly when applied to components that operate in very aggressive environments. This results in cost savings through reduced downtime and increased operational efficiency.

Customers include leading companies operating in the energy sectors, valve and pump manufacturing, industrial gas turbine, precision engineering and aerospace industries. The company has manufacturing facilities in the UK and USA.